| Issue |

Sust. Build.

Volume 7, 2024

Sustainability in the build environment

|

|

|---|---|---|

| Article Number | 2 | |

| Number of page(s) | 18 | |

| Section | Sustainable Building Materials and Construction | |

| DOI | https://doi.org/10.1051/sbuild/2024002 | |

| Published online | 24 June 2024 | |

Original Article

Applying infrared thermography to a latest residential building in France: case study, verifying dwellings national thermal regulations RT 2012 mainly thermal bridges assessment

University of Lorraine, Metz, France

* e-mail: harry.ramenah@univ-lorraine.fr

Received:

6

April

2023

Accepted:

28

April

2024

High-performance insulation and airtight building envelopes are the two most important factors to optimize the building energy efficiency and thermal performance. However, thermal performance of building envelopes can be significantly affected by thermal bridging. Thermal bridges can take place at different locations of the building envelope, causing added transmission losses, increasing heat flow, lower inner surface temperatures. Thermal bridges are regarded in all national regulations for new buildings of all states of European Union (EU) but there are no specifications assessing balconies to wall junctions and the impact on the building thermal performance is not well regulated. In this paper, balcony to wall thermal bridge assessment using infrared thermography is highlighted. The originality is that, infrared thermography, has been applied to a real living latest building in the north east of France showing that there is noncompliance in the national regulations as some exigencies are not met. Thermography of thermal break windows and window doors has also revealed air leakage. The goal, is to illustrate that thermal imaging is a means of quality assurance to new building specifications and should include a clause specifying quality assurance procedure for balconies junction in national building regulations for all states of the EU.

Key words: Thermal bridges / building efficiency / infrared thermography / building energy performance / balcony

© H. Ramenah, Published by EDP Sciences, 2024

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

Reducing undesirable heat loss and heat gain is a fundamental aspect of reducing heating or cooling energy bills. Builders use to focus on high-performance insulation and airtight building envelopes [1–4] as the two most important factors in optimizing the building energy efficiency and thermal performance. Walls, roof and windows of the building envelope are significant ways of thermal energy loss. Therefore, it is necessary to increase thermal performance [5–8]. However, as all these elements surely play a crucial role, thermal bridging can drastically reduce a landowner’s investment in high-performance insulation. Moreover, for high-performance buildings the impact of thermal bridges [9–17] can become significant on heating energy requirement. We can just remind that thermal bridge occurs when a material of high thermal conductivity, such as concrete, penetrates or interrupts a layer of low thermal conductivity material, such as insulation.

Additional transmission losses due to thermal bridges lead to a higher heating energy need and are becoming important for low energy or high performance buildings [18,19]. Therefore, most European Union (EU) Member States’ have decided to legislate [20] thermal bridges in the framework of building energy performance regulations. Some states considered that thermal bridges must be kept as low as possible in renovated buildings but all of them agreed that the influence of thermal bridges should be conspicuously considered in new buildings. Methods that are used by EU States to quantify the maximum value (ψk) of linear thermal bridges is either by including numerical analysis assessment in national regulations for new buildings and/or for some States by realization of details checked by authorities during design and building construction. However, there is no mandatory procedure to check that the minimum requirements are met for good quality building junctions in order to cover energy impact and to avoid moisture occurrence due to faulty execution.

For example, in France, execution quality with regard to thermal bridges of new building is not performed and for finished building it is the energy performance certificate and air permeability test [21–25] certificate that are issued. Airtightness is an important aspect in building performance and the blower door test is done to seek for air leakage that is contributing to a poor performing of building envelop but is not effective for thermal bridges or missing thermal insulation. We can also emphasize that, in France, the blower door test and energy performance estimation are done to some random sample apartments in a building and it is the same certificate that is issued to the others. This measured air permeability is fed into carbon dioxide (CO2) emissions calculations.

Therefore, for new dwellings in France, another approach must be considered to assess and improve quality execution. In this study, a powerful technique such as infrared (IR) thermography [26–35] using thermal imaging cameras is proposed to determine position and magnitude of thermal bridges in new buildings. Thermal imaging is a means of quality assurance for these buildings. So, in this paper, we are illustrating the impact of balcony thermal bridges and missing thermal insulation in a building that was built in 2021 in the east of France and should hypothetically satisfy the national thermal regulations. This is a quantitative survey showing condensation risks and defects of surface areas and also air leakage at windows with thermal break.

In literatures, IR thermography has been applied to experimental campaign in hot box apparatus [36,37], to experimental validation in a test room setup [38,39], for characterization of thermal building in prefabricated building walls [40,41]. Quantitative IR thermography [42–48] has also been applied for the determination of the overall heat transfer coefficient (U-value) in building envelopes. The originality of this paper is a case study where IR thermography measurements are done under real living conditions for a latest occupied building during two winter seasons. This study case is showing cold at thermal bridges located at wall to wall and balcony to wall junctions and also due window frames leading to occupant discomfort, health and safety issues. This paper is organized as follows. Section 2 explains IR thermography and the physical characteristics for IR camera. Section 3 deals with thermal bridges. Thermal measurements and results are illustrated in Section 4.

Conclusion and recommendations are given in Section 5.

2 Infrared thermography

2.1 Infrared radiation and thermograms

When a building is heated during winter season, heat flows through the building components (wall, windows. etc) due temperature difference between inside and outside the building. The resistance to heat flow varies with the properties of the building materials and thickness. This heat flow or leakage can be measured using a heat flux sensors or observed by infrared camera. IR radiation is a type of radiant energy that is invisible to human eyes but that can be felt as heat. Within the electromagnetic spectrum, IR radiation is just beyond the limit of red visible light but above microwaves.

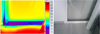

All objects above the absolute temperature (T) emit IR radiation and the quantity of that radiation emitted by the object generally varies with its surface temperature that is proportional to T4. The amount of IR radiation emitted is also affected by the efficiency of the surface radiating IR also known as emissivity (ε) [49–51]. The correlation between IR intensity and temperature is converted to a map of apparent temperature that is based on some assumptions such as variations in emissivity and this is considered in another section below. The thermal images from the thermal camera is known as thermograms and calibrated temperature thermal images is denoted as thermography. An example of a thermogram is indicated in Figure 1.

The scale and numerical values beside the image shows the relative temperatures due to different colors in the image.

When thermograms are reproduced with a temperature scale the apparent temperature can also be seen at each point. There are several sets of palettes that are commonly used to show the temperature differences. In this study, the rainbow palette is used as indicated in Figure 1. The minimum temperature in the image is indicated by the lowermost value on the temperature scale and the maximum temperature is indicated by the uppermost value.

Areas that are black in the image is at a temperature lower than the lowermost value whereas white parts are warmer than the uppermost value.

|

Fig. 1 Example of a thermal image. |

2.2 Emissivity

The emissivity of the surface of a material is its effectiveness in emitting energy as thermal radiation. In other words, it describes how well an object emits IR radiation. A black body is a material that is a perfect emitter of heat energy and has an emissivity value of 1. It is calculated as the ratio of the thermal radiation from an object surface to the radiation from an ideal black body radiation at the same temperature. This ratio ranges from 0 to 1. In reality, there are no perfect black bodies and all objects are emitting IR radiation at less than 100% and having emissivity values of less than one. The emissivity varies from object to object and depends upon chemical makeup, geometry and temperature. As all object are imperfect emitters, the total radiation from an object could be a combination of absorbed, transmitted and reflected radiations. Transmitted radiation is the one that passes through the object of interest, reflect radiation is radiation from a source in front of the object and that reflects off the object surface.

Let us consider, an object which is not a black body in an enclosure, a room for example and E watt of radiation falls on each square meter of the body’s surface. If the object absorbs a fraction α of the incident radiation noted as αE (W/m2) and radiation that the object does not absorb is therefore (E- αE), it reflects or transmits. At equilibrium, the total power leaving the object/m2 is equal to the total power falling upon it, E (W/m2). The power emitted by the object that must be added to that reflected and transmitted is therefore αE (W/m2). The ratio of the total power radiated/m2 of the object, to that emitted by a black body at the same temperature is therefore noted as ε = αE/E = α. Hence, at thermal equilibrium the total emissivity of the object is equal to its total absorption factor.

Moreover, most bodies are colored they transmit or reflect some wavelengths better than others. They must absorb these wavelengths weakly and must radiate them weakly. Kirchhoff [16] showed that the spectral emissivity of a body, for a given wavelength, is equal to its spectral absorption factor for the same wavelength, then ελ = αλ. In this study and for a perfect use of the thermal camera, this factor, reflected temperatures and environmental conditions are considered for a correct interpretation of thermal images.

2.3 Indoor assessments

Materials with a high emissivity show their true temperature better than those with low emissivity. Common building materials such as brick, concrete and paint have a high emissivity of around 0.9. Hence, before internal measurements with the IR camera of each zone in the building, all objects and environments were considered at thermal equilibrium of the IR camera. Hence, the emissivity value is set to one (ελ = αλ) on the IR camera and internal or reference temperature should always be indicated for all thermograms. The angle of view is always perpendicular to the measured radiation as IR radiation is reduced and temperature can be underestimated for measurements further from the perpendicular. For this study case, the room temperature was at 21 °C, 40% internal humidity and outside temperature was at 5 °C during the winter season.

2.4 Thermal camera

Infrared cameras are sometimes called black bodies and have integrated temperature control electronics. There is a wide range of IR camera and they differ in thermal sensitivity, image resolution. For this study, the IR camera that had been used is the professional measuring instrument Testo 885. It is a Testo superResolution [52,53] technology with 640 × 480 pixels, thermal sensitivity <30 mK and a spectral range from 7.5 to 14 μm. The field of view / minimum focus distance is given for different lens such as 30° × 23°/ 0.1 m and 11° × 9° / 0.5 m. The output visual image size is 3.1 MP for a minimum focus distance of 0.5 m. It can also display real image. The IR camera is also equipped with radio humidity probe for automatic humidity measurement and value transfer in real time. The high quality IR measurement system means that energy losses or thermal bridges in buildings can be reliably detected.

2.5 Temperature index

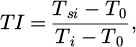

Cold surfaces naturally tend to be the first surfaces to experience condensation. One of the best metrics for assessing the condensation risk is the Temperature Index (TI) of a specific detail. TI is a dimensionless factor that defines the thermal performance of an area of building wall and can be calculated for a surface area on the thermal image. The TI that is used as an indicator of the likelihood of condensation is defined as follows:

where,

Tsi = Internal surface temperature

Ti = Internal ambient temperature

T0 = External ambient temperature.

For dwellings the value of TI should not be less than 0.75. In this study, TI should be applied to a zone of missing thermal insulator.

3 Thermal bridges

Thermal bridging [54–57] in building construction occurs when thermally conductive materials penetrate through the insulation creating areas of significantly reduced resistance to heat transfer. Thermal bridges can take place at different locations of the building envelope and can result in increased heat flow, causing added transmission losses, lower inner surface temperatures and possibly moisture problems. Most often, thermal bridges are created at the level of floor to wall, door to wall junctions, roof to wall junctions, ceilings to wall junctions and openings to the outside such as doors or windows. In this paper, we should consider thermal bridges, mainly wall to wall junctions, balcony to wall junctions and due to window frames. As already indicated, one of the effects of thermal bridges is increased heat loss through the wall, leading to higher operating costs. But, in this study case, detection of cold at the thermal bridge locations is leading to occupant discomfort, health and safety issues. Also, the design office that has issued the energy performance certificate has neglected thermal bridges at balconies, resulting in an under estimation of the total heat flow through the building envelope.

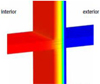

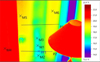

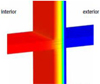

The thermal bridge effect at a vertical wall and balcony which is an extension of the concrete ceiling without thermal break is modelled [58,59] in Figure 2. In that figure, the red surface is the inner warm surface while the blue surface is the outer one; the color gradient from yellow to clear blue is showing heat flow to the outside through the balcony slab and the linear thermal bridge is the one that is measured by thermal camera. The temperature model distribution with thermal break is illustrated in Figure 3. In that figure, thermal break is providing a continuous insulating layer and has significantly reduced heat loss.

A number of numerical and experimental research studies [60–62] were published on finding solutions to reduce the heat loss across the balcony slabs.

They also neglected the thermal bridge effect at a concrete beam embedded in an external wall as represented in Figure 4. In this study case, the considered building has cantilevered balconies which is the most critical thermal bridges in a building envelope and more when cantilevers are non-insulated. Figure 5, illustrates a real image of the regarding building for this study case with cantilevered balcony. The concerning apartment is the upper ground floor indicated by the blue frame in Figure 5.

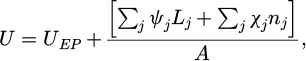

The main interest is impact of thermal bridge details on the building performance. Therefore the effects of thermal bridging transmittances must be included in whole building energy performance that is initially determined by the design office using the appropriate linear heat transmittance (ψ) and point heat transmittance (χ) factors. The effective heat transmittance (U) that must be used is written as follows:

Where UEP is the initial transmittance value determined in the energy model or calculation and n is the number of point thermal bridges (PTB) in the analysis area and A is the total surface area. Further explanation can be found in literature [63]. However, in the experimental section we should not consider PTB as they were not observed during IR thermal survey.

|

Fig. 2 Heat flow through balcony slab. |

|

Fig. 3 Heat flow with thermal break. |

|

Fig. 4 Embedded beam in a wall. |

|

Fig. 5 Real image of the concerning building at upper ground. |

4 IR measurements

The considered building for this study case is illustrated in Figure 5 and is supposed to be an example of a latest high performance building in France as it was finished in year 2021. The building is in the north-east of France which has a semi-continental climate characterized by cold and grey winters, accompanied by frequent snowfalls. The average temperature of the coldest months is nearly 1 °C. There can be cold spells, in which temperatures can drop as low as −10 °C or even below. Experimental conditions for the IR measurements are indicated in Section 2.3. The architectural design of the concerning apartment is illustrated in Figure 6 with internal insulation and the total surface area is 110 m2. The colored lines should indicate IR thermal measurements zones and orientations at each step of this study.

|

Fig. 6 Architectural plan of the apartment in the case study building. |

4.1 Wall to wall thermal bridge

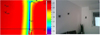

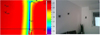

The wall to wall thermal bridge is the master bedroom, having a north orientation, and indicated by the red line in Figure 6. The thermogram is showed in Figure 7a and the corresponding real image is illustrated on the right side to the thermal image.

The wall containing the window in the real image is an insulated wall facing the outside and is at a junction with an internal load-bearing wall.

The blue color in the IR image indicates the wall to wall thermal bridge. This is identified in the thermogram by areas with lower surface temperature (blue color) in relation to intact areas (red colors).

The black bird which is a dark object is considered as the reference (reflection) temperature at 20.9 °C and the measured room temperature is 21 °C indicating that measurements are done in an optimal condition. M1 to M5 in the thermogram, are measured temperatures by IR camera as indicated in Table 1. The reference temperature is M4 (black object) as indicated by the observation column in Table 1 and M1 is the lowest temperature at 14.6 °C. M5 is a random point showing that the red color is at the reference temperature.

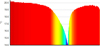

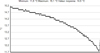

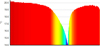

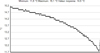

The line P1 in the thermal image is the temperature profile and plotted in Figure 8, showing a substantial temperature drop at the wall junction. Therefore, this zone is very sensitive to moisture and uncomfortable spaces due to high difference in surfaces temperatures. The insulation layers for this kind of junction that was supposed to reduce heat losses, had increased the thermal bridging impact. If insulation layers were extended to the internal wall, then this thermal bridge would have been avoided beside the augmentation in cost of construction.

It is also interesting to point out that temperatures M2 & M6 are part of the balcony thermal bridge.

The lower part of this wall to wall thermal bridge is showed in Figure 9 with the corresponding real image. In Table 2, the lowest measured temperature is close to 13 °C indicated by M1, for a reference temperature 20.8 °C indicated by M3, which is a dark alarm clock in the real image. Line P1 in the thermal image is the profile temperature that is plotted in Figure 10. The difference between the reference temperature and lowest temperature in the thermal bridge is 7.9 °C.

This thermal bridge is again caused by a lack of extension of the insulation on the uninsulated wall or a missing of thermal break at the walls junction during construction. The colors in the thermal image have been standardized in the Testo software for a better overview of temperature variation.

The next wall to wall thermal bridge is in another bed room, the green line in Figure 6. The thermal bridge again is at the junction of the internal bearing wall and an insulated wall facing the outside but in a south orientation. The thermograms and corresponding real image are displayed in Figure 11. Table 3, is indicating temperatures at variant locations in the thermal image. The temperature difference is nearly 5 °C between the lowest temperature in the thermal bridge and the room temperature.

|

Fig. 7 Left is the thermogram of a wall to wall thermal bridge and real image on the right. |

Measured temperature at different zone in the IR image.

|

Fig. 8 Substantial temperature drops due to wall to wall thermal bridge. |

|

Fig. 9 Lower part of the wall to wall thermal bridge. |

Measured temperature at the lower part.

Measured temperatures for another wall to wall thermal bridge.

|

Fig. 10 Profile temperature of line P1 in the thermal image. |

|

Fig. 11 On the left, another wall to wall thermal bridge and the real image on the right. |

4.2 Balcony to wall junctions

Traditionally, balconies have been constructed by extending the concrete slab through the wall into the outside. Such a balcony design is a prime example of a thermal bridge which allows the heat within the building to easily escape along that concrete slab. In this sub section, IR measurements of balcony to wall junctions should be considered and results should follow the similar presentations as in the previous section.

The positioning of the balcony to the walls is showed in Figure 5. As there are many balconies to wall thermal bridges all around the colors in Figure 6, it seems convincing to present the most relevant results.

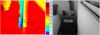

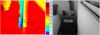

This first type of thermal bridge is along the dark and yellow lines as indicated in Figure 5 including the junction between the two walls. The thermogram and its corresponding real image are displayed in Figure 12.

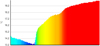

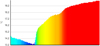

The wall containing the clock in the real image has a north orientation and the perpendicular wall has a north west orientation. The reference temperature is taken as M2 due to the thick dark frame of the clock. It can be concluded that an equilibrium condition is reached as the ceiling temperature M1 is the same as M2. Table 4, gives temperatures at different locations. The least temperature is given at M5 position whereas M3 & M4 are temperatures at the wall to wall junction. Line P1 is temperature profile in the balcony wall thermal bridge and is represented in Figure 13. The ultimate temperature difference is 7.2 °C. It is clear, that this balcony thermal bridge should cause the highest percentage of energy loss. The balcony slab board that is working as heat transfer fins has caused a direct heat flow path between spaces with different thermal conditions.

It is clear that there can be no significant representation of temperature profile for the other balcony to wall junction in thermal image as the IR camera was only facing the studied junction. The reason is also specified in Section 2.3.

The yellow line in Figure 6 is the bridge in the north west orientation and above the window door. The concerning balcony and window door are also visible in Figure 5. The results are presented in Figure 14 and Table 5. This thermal bridge is substantial as it still appears even behind the curtain rail in a clear blue color. The greatest temperature difference is 5.7 °C.

The following results are at the angle between the yellow and clear blue lines, that is between the south and south west orientation. In this case, the line P1 is not very significant as the IR camera in Figure 15 was facing the angular zone. The plot is simply indicating the temperature drop at the corner. Table 6 is the corresponding temperatures at several locations in the IR image.

The profile temperature along the balcony thermal bridge facing the south orientation is indicated in Figure 16. The linear part of the graph is not significant due the IR camera position as explained in Section 2.3.

The balcony thermal bridge is all around the building structure and we have chosen to give results for this last junction at the orange line in Figure 6. This zone has a south orientation. The least measured temperature at M1 position in the thermogram of Figure 17 is 16.6 °C as indicated in Table 7. The line P1 is the temperature profile along the balcony wall thermal bridge and represented in Figure 18. We retain a temperature difference of 4.4 °C for this thermal bridge.

|

Fig. 12 Balcony wall thermal bridge on the left and real image on the right. |

Temperature at different locations in IR image.

Measured temperatures for another wall to wall thermal bridge.

|

Fig. 13 Temperature profile in the thermal bridge in the IR image. |

|

Fig. 14 Left: Balcony thermal bridge along the yellow line. The real image on the right. |

|

Fig. 15 Left: Thermograms between yellow and clear blue lines. Real image on the right. |

The corresponding temperatures of IR image.

|

Fig. 16 Temperature profile of P1 in the IR image. |

|

Fig. 17 Left: Thermogram of the room at orange line and the corresponding real image on the right. |

The corresponding temperature in the thermogram.

|

Fig. 18 Temperature profile along the thermal bridge in the thermogram. |

4.3 Concrete beam to wall junction

In this sub section, a particular case is presented concerning the embedded beam in a wall. This zone is indicated by the indigo color in Figure 6. This zone has a south orientation.

The beam is clearly visible on the outside thermogram at various floor of the building as illustrated in Figure 19. The thermogram of this thermal bridge and the real image are illustrated in Figure 20.

The corresponding temperatures in the thermogram are indicated in Table 8.

This thermal bridge was caused by the beam itself and the heat flow is imaged in Figure 4 of Section 3. The reference temperature is determined by the dark object on a branch of the tree in the real image. The maximum temperature difference is nearly 5 °C. The joints in walls play a major role of heat loss and gain between indoor and outdoor environments, which is the major cause of the “ghosting” phenomenon that is appearance of dark or discoloured patterns.

|

Fig. 19 Beam wall thermogram from outside. |

|

Fig. 20 Thermogram and real image of the slab wall junction. |

Temperatures at various locations in the thermogram.

4.4 Missing thermal insulator

Missing thermal insulator have been listed at few zones of the apartment during the thermal survey. One of the zone is between the yellow and clear blue lines in Figure 6. It seems that there are missing thermal insulator at various area of the wall and only results regarding the lower part of the wall are considered. We should also consider the temperature index for an area on the thermal image as explained in Section 2.5. Internal temperatures at different locations of that zone were also measured by a contact temperature sensor PT 100 and are similar to those of the thermal camera. During this survey, the internal ambient temperature, Ti, was 21 °C and the external ambient temperature T0 was 5 °C. Various parts of missing thermal insulator are visible on the thermogram of Figure 21 and the corresponding real image on the right of the thermal image. The measured internal surface temperatures are given in Table 9.

M3 is considered as the internal surface temperature Tsi at 16.1 °C for the temperature index determination given by equation 1 in Section 2.5 and the other temperatures in this equation are indicated above. The determined TI value is 0.694.

For dwellings the value of TI should not be less than 0.75 as this value matches an internal surface temperature of 13.8 °C when the usual inside temperature is 20 °C and outside temperature is −5 °C. As consequence, missing insulation should bring condensation that would arise if the outside temperature was below −5 °C or the inside air was more saturated with water vapor.

|

Fig. 21 Thermogram of the zone of missing insulator and the real image on the right. |

The corresponding temperature of the thermogram.

4.5 Heat loss by thermal break windows

All the apartments of this new dwelling are equipped with double glazed windows filled with an inert gas such argon or krypton and are essentially thermal break insulated aluminum windows. Thermal breaks are a material placed inside the aluminum window frame to minimize heat loss through the frame. They are able to cut this heat flow because they are also made up of materials that can interrupt thermal conductivity. This material is usually PVC.

Therefore, windows thermal survey has been performed by the thermal camera for heat loss detection or air leakage. In this section, only relevant results are presented.

The following results are for the window in the master bedroom, red line in Figure 6. The window is facing the north. The window thermogram is illustrated in Figure 22.

Measured temperatures at various positions of the window are given in Table 10. M1 is the reference temperature. The M2 temperature is at 14.8 °C indication a small air leakage due a poor installation. M3 to M7 are temperatures around the window frame showing low temperatures comparing to the reference temperature. The colder the window frame the greater the conductive current and this great temperature difference is always causing air movement cycle that is felt a lot like a window draft by occupants. The constant cold surface temperatures make the bedroom especially unpleasant and uncomfortable and on end having major effects on quality of life. Moreover, the IR image of Figure 23 is illustrating an air leakage by the purple color at the bottom part of the window sash.

Table 11 shows temperatures at the cold-air leaks surrounding the sash.

Figure 24, is the thermogram of a window door of the room indicated by the orange line in Figure 6. The thermogram, is not only showing low temperatures at the bottom part of window frame but also air leakage along line P1 and the temperature profile is indicated in Figure 25. Table 12, are temperatures at the window door frame.

|

Fig. 22 Window thermogram on the left and real image on the right. |

Temperatures at various locations in the thermal image.

|

Fig. 23 Left: Air leakage at the lower part of the window. Real image on the right. |

Temperatures in air leakage.

Lowest temperatures at the window door.

|

Fig. 24 Left: Thermogram of door window and the real image on the right. |

|

Fig. 25 Temperature profile at P1 in the thermogram. |

4.6 Air speed at window door

In face of the unexpected temperature profile in Figure 26, it seems interesting to perform another test at the windows to highlight the air leaking. A wireless smart probe such as Testo 405i thermal anemometer has been used to measure the air speed around all the windows.

The probe position was initially determined in the thermal image such the one along line P1 in Figure 25 and as illustrated in Figure 26. The air speed was measured between 10 min and 2 h.

Only two relevant results are presented. The first one is along the window door at the orange line in Figure 6. The air speed was measured for more than 2 h as illustrated in Figure 27 and it can be observed that the air speed difference is between 0.5 m/s to 1.6 m/s.

The other test was performed on the window door which is at the yellow line in Figure 6, in a north west direction. The air speed was measured for nearly 10 min and is represented in Figure 28. We can see that the maximum air speed is closed 1 m/s. Hence, these results attest that there exist an air leakage at some window doors.

|

Fig. 26 Probe position to measure air leaking. |

|

Fig. 27 Measuring air speed at the window door facing the south. |

|

Fig. 28 Measuring air speed at the window door facing the north west. |

4.7 Heat transmittance results

In France and in the national regulations for new building exigencies intended for Ψ, the linear transmittance thermal bridges, between intermediate floors and facades should be less than 0.6 W/m K. Also, the overall linear thermal transmission ratio, ΨT = Σ(Ψ,L) / (Building overall Floor surface), of the whole building must be less than 0.28 W/m2(floo surface) K. However, there is no specification for Ψ, in the national regulations when the slab is an extended balcony slab with a concrete to concrete intersection. Therefore, for an estimation of power transmission loss (PTL) for this study case, we are comparing the PTL for two different Ψ values in Table 13. The first column represents the expected results in the France national regulation RT 2012. The second column is the PTL value using the linear transmittance Ψ = 0.6 W/m K but with a mean difference temperature of 4 °C as measured by the thermal camera at the balcony thermal bridge. The third column is similar to the second column but with Ψ = 0.805 W/m K as determined in [64]. The fourth column is the PTL due to thermal bridge at wall to wall for a mean temperature difference of 5 °C with Ψ = 0.3 W/m K as considered in the national regulation software. The total length of balcony thermal bridge is 26.76 m and the total height of wall to wall thermal bridge is 5 m. The total floor surface area is 110 m2.

Therefore, for this study building and considering the overall linear thermal transmission ratio ΨT of the whole building in RT 2012, then the overall power loss per m2 is equal to 0.207 for RT2012, whereas it is equal to 0.645 when Ψ = 0.6 W/m K and equal to 0.843 when Ψ = 0.803 W/m K. This requirement in the national regulations is not met.

Comparing overall thermal transmission of the study building.

5 Conclusion

This study assessed the influence of thermal bridges on heat losses in an internal insulation layers’ apartment of a recent building using IR thermography which is a non-destructive method in building sector. The thermal camera was used in optimal indoor conditions and the most appropriate method was applied for this thermographic survey. It has been highlighted that junction between an external insulated wall and an internal non-insulated wall has not lead to a significant reduction in the heat losses but has increased the thermal bridging beside the augmentation in the cost of construct. In this paper, a great part of balcony thermal bridge has been considered comparing to all other thermal bridges, as the former present a large cross-sectional area ratio of the exterior building envelopes and has a greater negative impact on the energy performance. It is also emphasized that heat loss in the high-rise building is due to non-insulated concrete slab such as balconies. Air pressurization using the blower door had allowed the building to pass the airtightness test. However, thermography of thermal break windows had revealed air leakage and quantified by measurement with a thermal anemometer probe and where the air speed was nearly 1,5m/s. So, this study has underlined the occurrence of thermal bridges due to faulty execution causing heat lost, occupant discomfort and in long run may affect the indoor climate. Moreover, there is noncompliance in the national regulations as some exigencies, such as the overall linear thermal transmission ratio, are not met.

It is clear that thermal bridges are regarded in all national regulations for new buildings of all states of the European Union. However, thermal bridges and energy consumption inspections during and after the building process especially for large buildings are not regular and mandatory processes. As for some recommendations, energy specialists should do inspections by taking measurements, pictures before, during and after the building process. The number of blower door test need greatly to be increased for buildings. One of the most widely recommended solutions to the balcony slab thermal bridge problem is to introduce thermal breaks or insulated concrete curbs and make it compulsory in thermal regulation. New building specifications should include a clause specifying thermal imaging as a means of quality assurance.

Funding

This article received no external funding.

Conflicts of interest

The author declares no conflict of interests.

Data availability statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

- I. Poza-Casado, P. Rodríguez-del-Tío, M. Fernandez-Temprano, M.-A. Padilla-Marcos, A. Meiss, An envelope airtightness predictive model for residential buildings in Spain, Build. Environ. 223, 109435 (2022) [CrossRef] [Google Scholar]

- J.P. Fine, J. Gray, X. Tian, M.F. Touchie, An investigation of alternative methods for determining envelope airtightness from suite-based testing in multi-unit residential buildings, Energy Build. 214, 109845 (2020) [CrossRef] [Google Scholar]

- Y. Ji, L. Duanmu, S. Hu, Measurement and analysis of airtightness safeguard measures for typical ultra-low energy buildings, Energy Built Environ. 5, 348–363 (2023) [Google Scholar]

- C. Carbonaro, Y. Cascone, S. Fantucci, V. Serra, M. Perino, M. Dutto, Energy assessment of a PCM-embedded plaster: embodied energy versus operational energy, Energy Procedia 78, 3210–3215 (2015) [CrossRef] [Google Scholar]

- S. Dardouri, S. Mankai, M.M. Almoneef, M.M.J. Sghaier, Energy performance based optimization of building envelope containing PCM combined with insulation considering various configurations, Energy Rep. 10, 895–909 (2023) [CrossRef] [Google Scholar]

- E. Tunçbilek, M. Arıcı, M. Krajcík, D. Li, S. Nizetic, A.M. Papadopoulos, Enhancing building wall thermal performance with phase change material and insulation: a comparative and synergistic assessment, Renew. Energy 218, 119270 (2023) [CrossRef] [Google Scholar]

- N.-Y. Joo, S.-Y. Song, Improvement of thermal insulation performance of precast concrete curtain walls for apartment buildings, Energy Build. 296, 113350 (2023) [CrossRef] [Google Scholar]

- Y. Zhang, X. Sun, M.A. Medina, Thermal performance of concrete masonry units containing insulation and phase change material, J. Build. Eng. 76, 107184 (2023) [CrossRef] [Google Scholar]

- S. Kim, J. Seo, H. Jeong, J. Kim, In situ measurement of the heat loss coefficient of thermal bridges in a building envelope, Energy Build. 256, 111627 (2022) [CrossRef] [Google Scholar]

- D. Borelli, P. Cavalletti, A. Marchitto, C. Schenone, A comprehensive study devoted to determine linear thermal bridges transmittance in existing buildings, Energy Build. 224, 110136 (2020) [CrossRef] [Google Scholar]

- J. Lu a, Y. Xue, Z. Wang, Y. Fan, Optimized mitigation of heat loss by avoiding wall-to-floor thermal bridges in reinforced concrete buildings, J. Build. Eng. 30, 101214 (2020) [CrossRef] [Google Scholar]

- S. Bergero, A. Chiari, The influence of thermal bridge calculation method on the building energy need: a case study, Energy Procedia 148, 1042–1049 (2018) [CrossRef] [Google Scholar]

- I. Garrido, S. Lagüela, P. Arias, J. Balado, Thermal-based analysis for the automatic detection and characterization of thermal bridges in buildings, Energy Build. 158, 1358–1367 (2018) [CrossRef] [Google Scholar]

- T. Theodosiou, K. Tsikaloudaki, S. Tsoka, P. Chastas, Thermal bridging problems on advanced cladding systems and smart building facades, J. Clean. Prod. 214, 62–69 (2019) [CrossRef] [Google Scholar]

- Morrison Hershfield limited, Building envelope thermal bridging guide, Research report, Toronto, ON, Canada, 2016 [Google Scholar]

- International Organisation for Standardization (ISO), Thermal bridges in building construction-linear thermal transmittance-simplified methods and default values,EN ISO 1468 3, Geneva, Switzerland, 2008 [Google Scholar]

- F. Asdrubali, G. Baldinelli, F. Bianchi, A quantitative methodology to evaluate thermal bridges in buildings, Appl. Energy 97, 365–373 (2012) [CrossRef] [Google Scholar]

- M. Bilardo, E. Fabrizio, From zero energy to zero power buildings: a new framework to define high-energy performance and carbon-neutral buildings, Sustain. Energy Technol. Assessments 60, 103521 (2023) [CrossRef] [Google Scholar]

- R.M. Palma, J.S. Ramos, M.C.G. Delgado, T.R.P. Amores, G. D’Angelo, S.A. Domínguez, Extending the concept of high-performance buildings to existing dwellings, Energy Build. 296, 113431 (2023) [CrossRef] [Google Scholar]

- European Parliament. Directive 2018/844/EU of the European Parliament and of the Council of 30 May 2018 amending Directive 2010/31/EU on the energy performance of buildings and Directive 2012/27/EU on energy efficiency, Official Journal of the European Union 75–91 (2018) [Google Scholar]

- B. Moujalled, B. Kolsch, A. Melois, V.S Leprince, Quantitative correlation between buildings air permeability indicators: statistical analyses of over 400,000 measurements, Energy Build. 298, 113566 (2023) [CrossRef] [Google Scholar]

- M. Pinto, J. Viegas, V.P. de Freitas, Air permeability measurements of dwellings and building components in Portugal, Build. Environ. 46, 2480–2489 (2011) [CrossRef] [Google Scholar]

- J. Hu, Z. Liu, G. Ma, G. Zhang, Z. Ai, Air infiltration and related building energy consumption: a case study of office buildings in Changsha, China, J. Build. Eng. 74, 106859 (2023) [CrossRef] [Google Scholar]

- NF EN 1026, Windows and doors-air permeability- test method, National standards and national normative documents, 2016 [Google Scholar]

- Technical standard 1, Measuring air permeability of building envelopes, The Air Tightness Testing and Measurement Association (ATTMA), 2007, Issue 2 [Google Scholar]

- A. Kirimtat, O. Krejcar, A review of infrared thermography for the investigation of building envelopes: advances and prospects, Energy Build. 176, 390–406 (2018) [CrossRef] [Google Scholar]

- M. O’Grady, A.A. Lechowska, A.M. Harte, Infrared thermography technique as an in-situ method of assessingheat loss through thermal bridging, Energy Build. 135, 20–32 (2017) [CrossRef] [Google Scholar]

- A. Kylili, P.A. Fokaides, P. Christou, S.A. Kalogirou, Infrared thermography (IRT) applications for building diagnostics: a review, Appl. Energy 134, 531–549 (2014) [CrossRef] [Google Scholar]

- M. O’Grady, A.A. Lechowska, A.M. Harte, Infrared thermography technique as an in-situ method of assessing the heat loss through thermal bridging, Energy Build. 135, 20–32 (2017) [CrossRef] [Google Scholar]

- X. Lu, A. Memari, Application of infrared thermography for in-situ determination of building envelope thermal properties, J. Build. Eng. 26, 100885 (2019) [CrossRef] [Google Scholar]

- G. Ferreira et al., Experimental analysis of the infrared thermography for the thermal characterization of a building envelope, Defect Diffus. Forum 326–328, (2012) [Google Scholar]

- A. Kylili, P.A. Fokaides, P. Christou, S.A. Kalogirou, Infrared thermography (IRT) applications for building diagnostics: a review, Appl. Energy 134, 531–549 (2014) [CrossRef] [Google Scholar]

- C.A. Balaras, A.A. Argiriou, Infrared thermography for building diagnostics, Energy Build. 34, 171–183 (2002) [CrossRef] [Google Scholar]

- M. Fox, S. Goodhew, P. De Wilde, Building defect detection, external versus internal thermography, Build. Environ. 105, 317–331 (2016) [CrossRef] [Google Scholar]

- M. O’Grady, A. Agnieszka Lechowska, A.M. Harte, Application of infrared thermography technique to the thermal assessment of multiple thermal bridges and windows, Energy Buid. 168, 347–362 (2018) [Google Scholar]

- G. Baldinelli, F. Bianchi, A. Rotili et al., A model for the improvement of thermal bridges quantitative assessment by infrared thermography, Appl. Energy 211, 854–864 (2018) [CrossRef] [Google Scholar]

- Z. Shen, A.L. Brooks, Y. He, S.S. Shrestha, H. Zhou, Evaluating dynamic thermal performance of building envelope components using small-scale calibrated hot box tests, Energy Build. 251, 111342 (2021) [CrossRef] [Google Scholar]

- F. Bianchi, Al. Pisello, G. Baldinelli, F. Asdrubali, Infrared thermography assessment of thermal bridges in building envelope: experimental validation in a test room setup, Sustainability 6, 7107–7120 (2014) [CrossRef] [Google Scholar]

- E. Bauer, E. Pavón, E. Barreira, E.K. De Castro, Analysis of building facade defects using infrared thermography: laboratory studies, J. Build. Eng. 6, 93–104 (2016) [CrossRef] [Google Scholar]

- L. Zalewski, S. Lassue, D. Rousse, K. Boukhalfa, Experimental and numerical characterization of thermal bridges in prefabricated building walls, Energy Conv. Manag. 51, 2869–2877 (2010) [CrossRef] [Google Scholar]

- K. Wakili, H. Simmler, T. Frank, Experimental and numerical thermal analysis of a balcony board with integrated glass fibre reinforced polymer GFRP elements, Energy Build. 39, 76–81 (2007) [CrossRef] [Google Scholar]

- A. Marshal et al., Variations in the U-value measurement of a whole dwelling using infrared thermography under controlled conditions, Buildings 8, 46 (2018) [CrossRef] [Google Scholar]

- I. Nardi et al., U-value assessment by infrared thermography: a comparison of different calculation methods in a Guarded Hot Box, Energy Build. 122, 211–217 (2016) [CrossRef] [Google Scholar]

- B. Tejedor, E. Barreira, R.M.S.F. Almeida, M. Casals, Automated data-processing technique: 2D map for identifying the distribution of the U-value in building elements by quantitative internal thermography, Autom. Constr. 122, 103478 (2021) [CrossRef] [Google Scholar]

- B. Tejedor, E. Barreira, R.M.S.F. Almeida, M. Casals, Thermographic 2D U-value map for quantifying thermal bridges in building façades, Energy Build. 224, 110176 (2020) [CrossRef] [Google Scholar]

- R. Albatici, A.M. Tonelli, M. Chiogna, A comprehensive experimental approach for the validation of quantitative infrared thermography in the evaluation of building thermal transmittance, Appl. Energ. 141, 218–228 (2015) [CrossRef] [Google Scholar]

- P.A. Fokaides, S.A. Kalogirou, Application of infrared thermography for the determination of the overall heat transfer coefficient (U-value) in building envelopes, Appl. Energy 88, 4358–4365 (2011) [CrossRef] [Google Scholar]

- B. Mobaraki, F.J.C. Pascual, F. Lozano-Galant, J.A. Lozano-Galant, R.P. Soriano, In situ U-value measurement of building envelopes through continuous low-cost monitoring, Case Stud. Therm. Eng. 43, 102778 (2023) [CrossRef] [Google Scholar]

- N.P. Avdelidis, A. Moropoulou, Emissivity considerations in building thermography, Energy Build. 35, 663–667 (2003) [CrossRef] [Google Scholar]

- D. Especel, S. Matteı, Total emissivity measurements without use of an absolute reference, Infrared Phys. Technol. 37, 777–784 (1996) [CrossRef] [Google Scholar]

- S. Marinetti, P.G. Cesaratto, Emissivity estimation for accurate quantitative thermography, NDT&E Int. 51, 127–134 (2012) [CrossRef] [Google Scholar]

- FLIR Systems, ThermaCAM B2: operator’s manual, Flir Systems, Sweden, 2005 [Google Scholar]

- FLIR, Thermal imaging guidebook for building and renewable energy applications, 2018 [Google Scholar]

- EN ISO 10211, Thermal bridges in building construction heat flow and surface temperatures detailed calculations, 2017 [Google Scholar]

- A. Capozzoli, A. Gorrino, V. Corrado, A building thermal bridges sensitivity analysis, Appl. Energy 107, 229–243 (2013) [CrossRef] [Google Scholar]

- J. Hallik, T. Kalamees, The effect of flanking element length in thermal bridge calculation and possible simplifications to account for combined thermal bridges in well insulated building envelopes, Energy Build. 252, 111397 (2021) [CrossRef] [Google Scholar]

- H. Ge, F. Baba, Effect of dynamic modeling of thermal bridges on the energy performance of residential buildings with high thermal mass for cold climates, Sustain. Cities Soc. 34, 250–263 (2017) [CrossRef] [Google Scholar]

- S. Isokorb, Retrieved from: Thermal bridging guide, September (2018) [Google Scholar]

- V Harish, A. Kumar, A review on modeling and simulation of building energy systems, Renew. Sustain. Energy Rev. 56, 1272–1292 (2016) [CrossRef] [Google Scholar]

- A. Alhawari, P. Mukhopadhyaya, Thermal bridges in buildings envelopes an overview of impacts and solutions, Int. Rev. Appli. Sci. Eng. 9, 31–40 (2018) [Google Scholar]

- S. Aghasizadeh, B.M. Kari b, R. Fayaz, Thermal performance of balcony thermal bridge solutions in reinforced concrete and steel frame structures, J. Build. Eng. 48, 103984 (2022) [CrossRef] [Google Scholar]

- I . Susorova, B. Stephens, B. Skelton, The effect of balcony thermal breaks on building thermal and energy performance: field experiments and energy simulations in Chicago, IL, Buildings 1–24 (2019) [Google Scholar]

- J.H. Lienhard, A heat transfer textbook, fifth edition, Phlogiston Press, 2019 [Google Scholar]

- N. Norris, M. Lawton, P. Roppel, The concept of linear and point transmittance and its value in dealing with thermal bridges in building enclosures,Engineering, Corpus ID: 174771721, 2012 [Google Scholar]

Cite this article as: H. Ramenah: Applying infrared thermography to a latest residential building in France: case study, verifying dwellings national thermal regulations RT 2012 mainly thermal bridges assessment. Sust. Build. 7, 2 (2024).

All Tables

All Figures

|

Fig. 1 Example of a thermal image. |

| In the text | |

|

Fig. 2 Heat flow through balcony slab. |

| In the text | |

|

Fig. 3 Heat flow with thermal break. |

| In the text | |

|

Fig. 4 Embedded beam in a wall. |

| In the text | |

|

Fig. 5 Real image of the concerning building at upper ground. |

| In the text | |

|

Fig. 6 Architectural plan of the apartment in the case study building. |

| In the text | |

|

Fig. 7 Left is the thermogram of a wall to wall thermal bridge and real image on the right. |

| In the text | |

|

Fig. 8 Substantial temperature drops due to wall to wall thermal bridge. |

| In the text | |

|

Fig. 9 Lower part of the wall to wall thermal bridge. |

| In the text | |

|

Fig. 10 Profile temperature of line P1 in the thermal image. |

| In the text | |

|

Fig. 11 On the left, another wall to wall thermal bridge and the real image on the right. |

| In the text | |

|

Fig. 12 Balcony wall thermal bridge on the left and real image on the right. |

| In the text | |

|

Fig. 13 Temperature profile in the thermal bridge in the IR image. |

| In the text | |

|

Fig. 14 Left: Balcony thermal bridge along the yellow line. The real image on the right. |

| In the text | |

|

Fig. 15 Left: Thermograms between yellow and clear blue lines. Real image on the right. |

| In the text | |

|

Fig. 16 Temperature profile of P1 in the IR image. |

| In the text | |

|

Fig. 17 Left: Thermogram of the room at orange line and the corresponding real image on the right. |

| In the text | |

|

Fig. 18 Temperature profile along the thermal bridge in the thermogram. |

| In the text | |

|

Fig. 19 Beam wall thermogram from outside. |

| In the text | |

|

Fig. 20 Thermogram and real image of the slab wall junction. |

| In the text | |

|

Fig. 21 Thermogram of the zone of missing insulator and the real image on the right. |

| In the text | |

|

Fig. 22 Window thermogram on the left and real image on the right. |

| In the text | |

|

Fig. 23 Left: Air leakage at the lower part of the window. Real image on the right. |

| In the text | |

|

Fig. 24 Left: Thermogram of door window and the real image on the right. |

| In the text | |

|

Fig. 25 Temperature profile at P1 in the thermogram. |

| In the text | |

|

Fig. 26 Probe position to measure air leaking. |

| In the text | |

|

Fig. 27 Measuring air speed at the window door facing the south. |

| In the text | |

|

Fig. 28 Measuring air speed at the window door facing the north west. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.